QUALITY CONTROL

Global quality control practices are implemented in each production process.

Autostrada pays special attention to the quality of work. It is provided by technical supervision engineers with experience in the largest international companies.

In addition, the company has created a laboratory complex, which has no analogues in Ukraine, which allows implementing a systematic approach to improving the quality indicators and durability of road clothing and bridge structures.

It consists of:

• mobile laboratories (on the basis of which all basic tests necessary for construction works are performed directly on construction sites);

• the central laboratory (on the basis of which work is being carried out on the implementation of world methods for determining the fundamental properties of materials used in the construction of bridges and roads, in the conditions of their operation);

• mobile laboratories - with the help of which monitoring of road works and permanent comprehensive diagnostics of automobile roads are carried out.

The unique Central and certified laboratories at production bases are equipped with the most modern equipment from Matest, Testing AG, HMP, Silverson, ULAB, RadialTec.

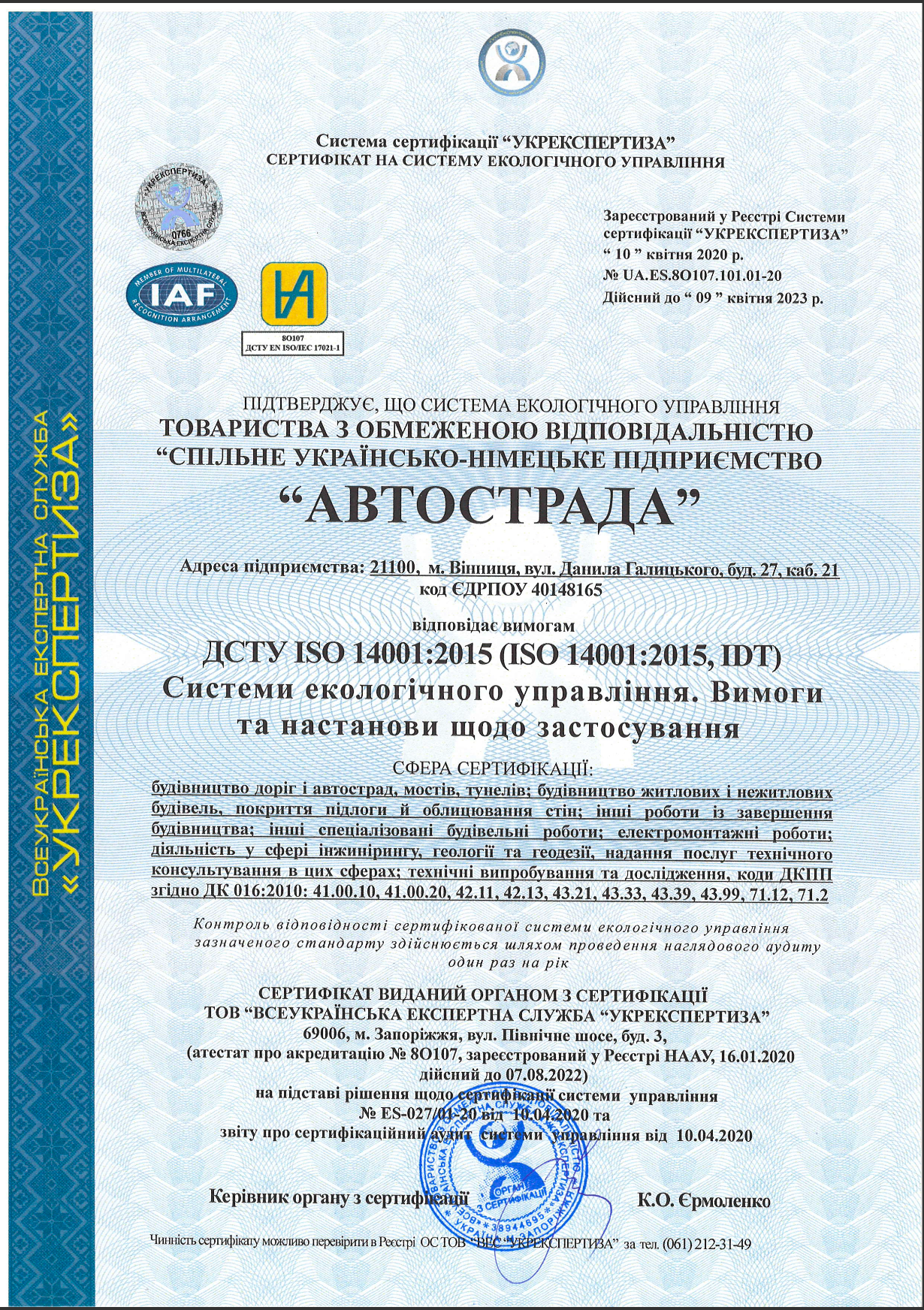

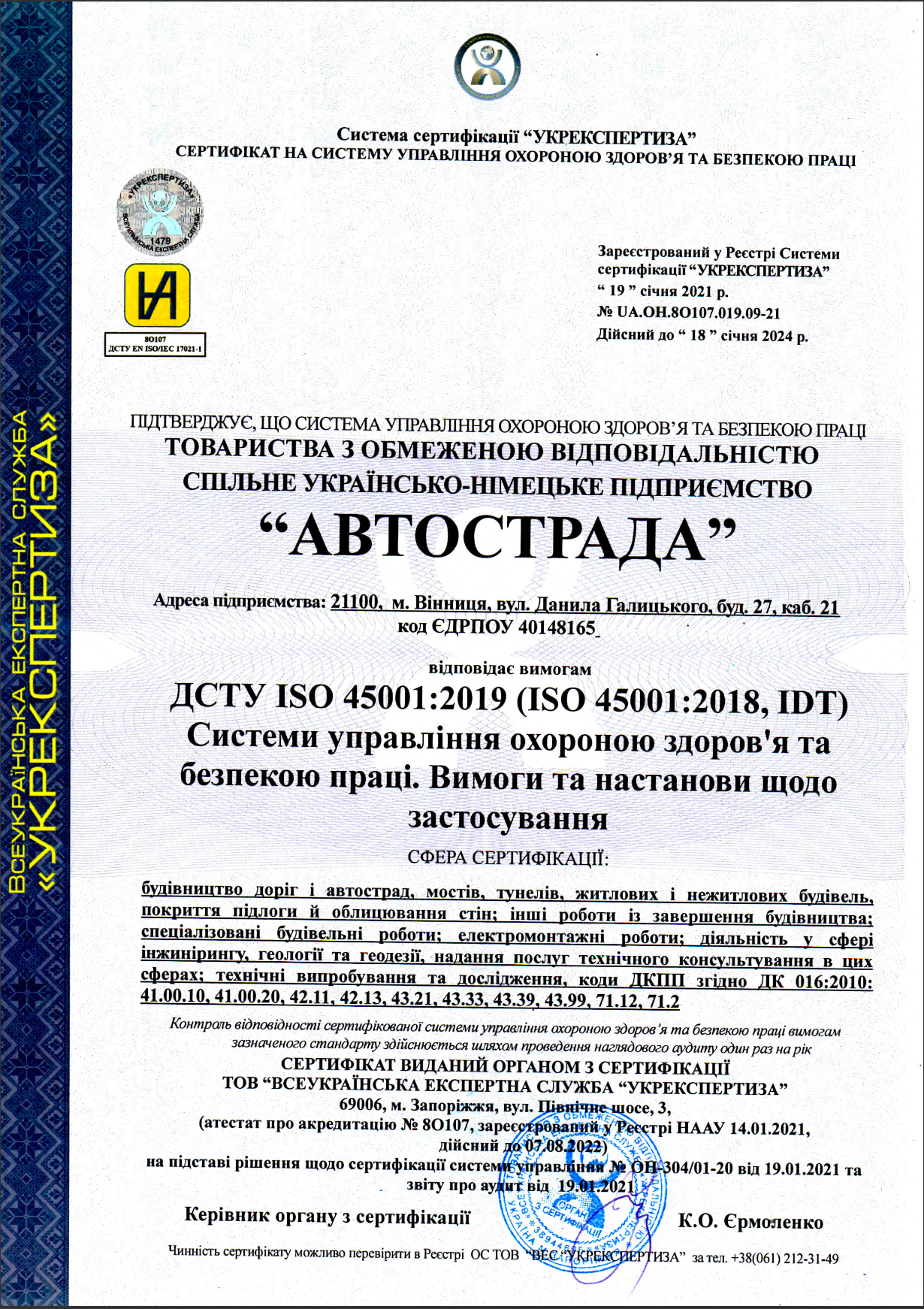

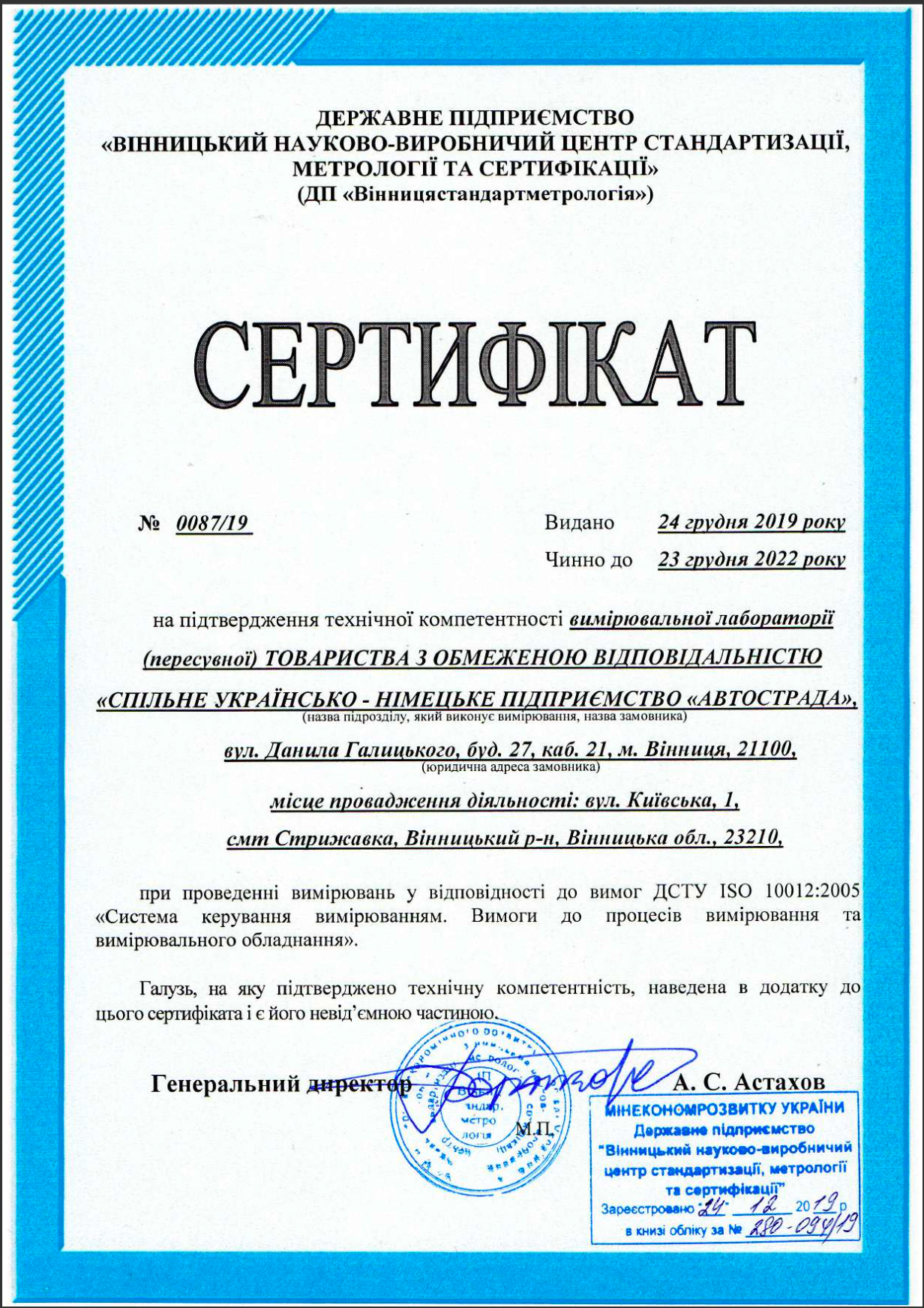

Autostrada has special certified laboratories, in accordance with the requirements of DSTU ISO 10012:2005. This allows to make a constant monitoring of the state of raw materials.

Incoming control of purchased materials and products

Thanks to the use of modern equipment, proven raw materials and monitoring of the quality of finished products, we guarantee that our product meets the requirements of strength, abrasion resistance, water absorption, frost resistance and sound absorption.

Control of production of asphalt concrete mixture

The quality of asphalt concrete mixtures is controlled at least twice a day every 600 tons according to DSTU B V.2.7-319:2016 for compliance with the requirements of DSTU B V.2.7-119:2011 "Asphalt concrete mixtures and asphalt concrete for roads and airfields" and DSTU BV.2.7- 127:2015 "Asphalt concrete and crushed stone-mastic asphalt concrete mixtures".

Asphalt concrete laying and compaction quality control

Laying and compaction of the asphalt concrete mixture and the quality of the asphalt concrete in the coating are controlled by selecting cores in accordance with the procedure stipulated in DBN V.2.3-4. Conclusions for each sample test are recorded in protocols, which are provided to the Services for Reconstruction and Development of Infrastructure in regions. In parallel, the services conduct an independent examination of the road surface.

Permanent geodetic control

Control at every stage of production

We carry out quality control in our own laboratories from the beginning of the production of the asphalt concrete mixture to the delivery of the finished road.

Quality standards

Autostrada complies with all European quality requirements, state standards and construction regulations and guarantees the highest level of work, which is confirmed by certificates.